About me

Hey There! I am Naufal Aditya Juniarahman

Hi, I’m Naufal Aditya Juniarahman, an aspiring Electrical Engineer with a passion for control systems, automation, and technical drafting. Currently completing my Bachelor of Engineering in Electrical Engineering at Gadjah Mada University, I have hands-on experience in both mechanical fabrication and electrical system design.

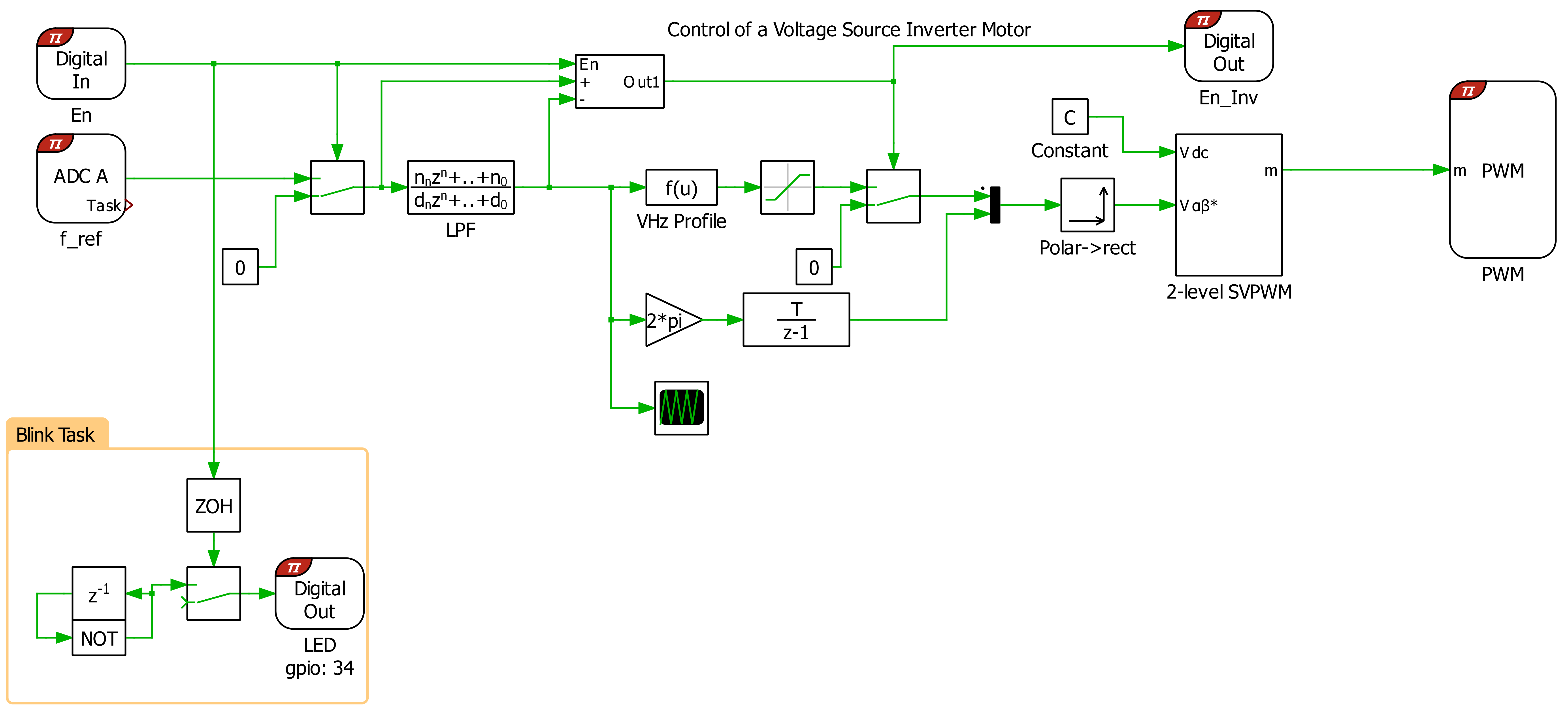

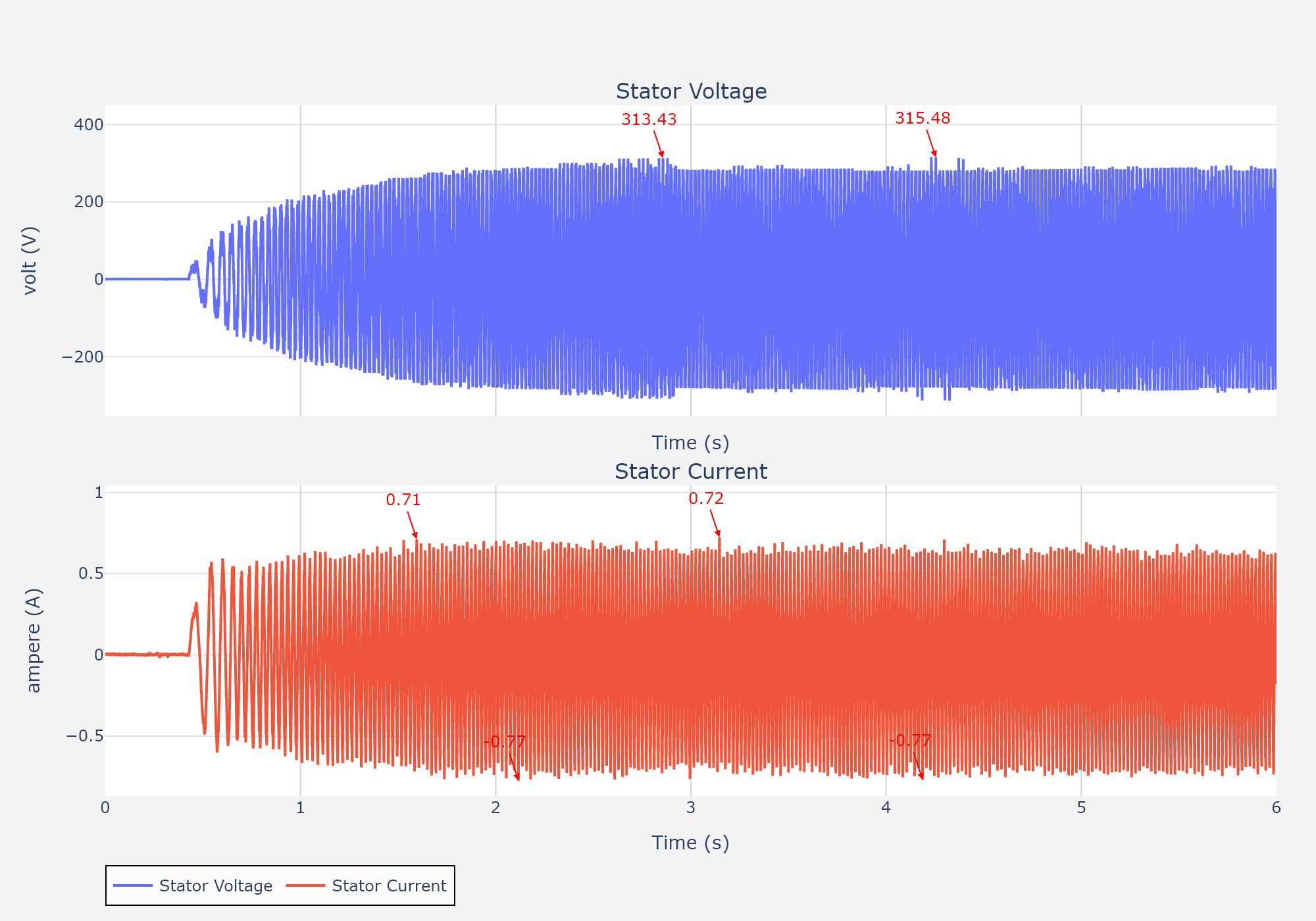

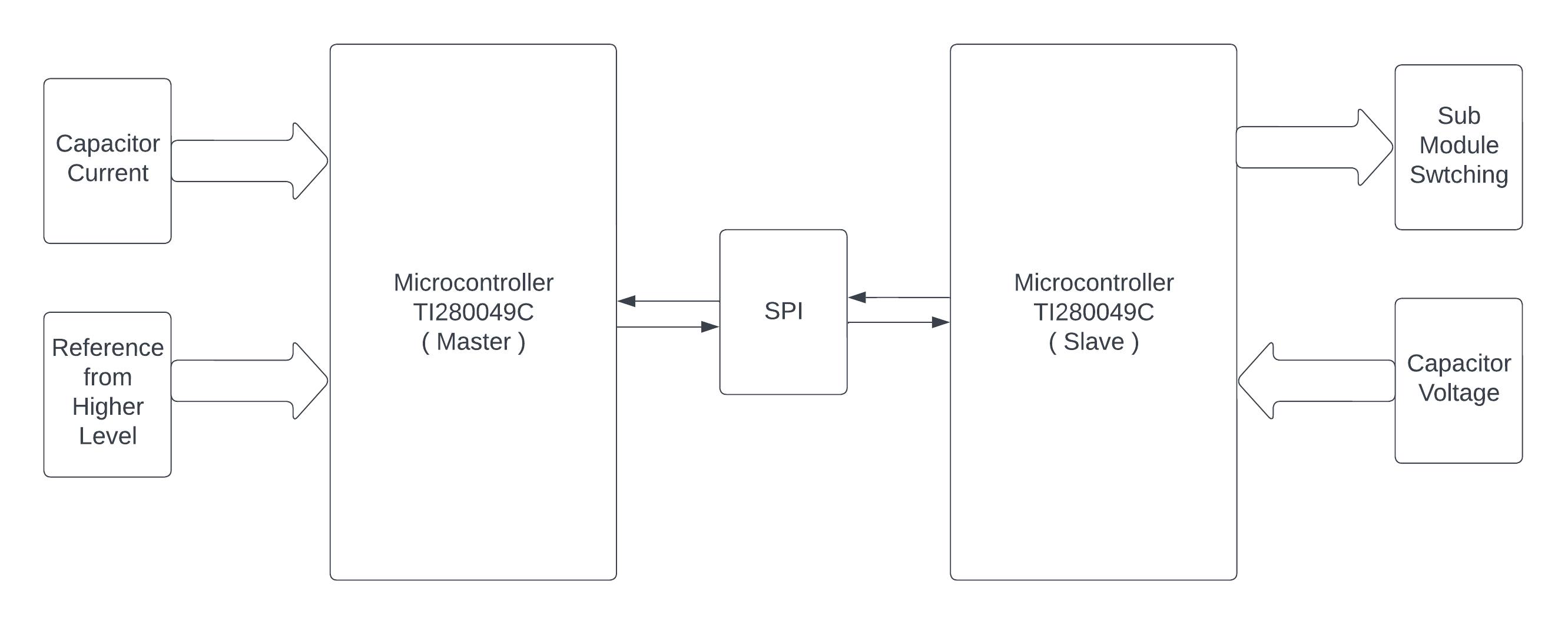

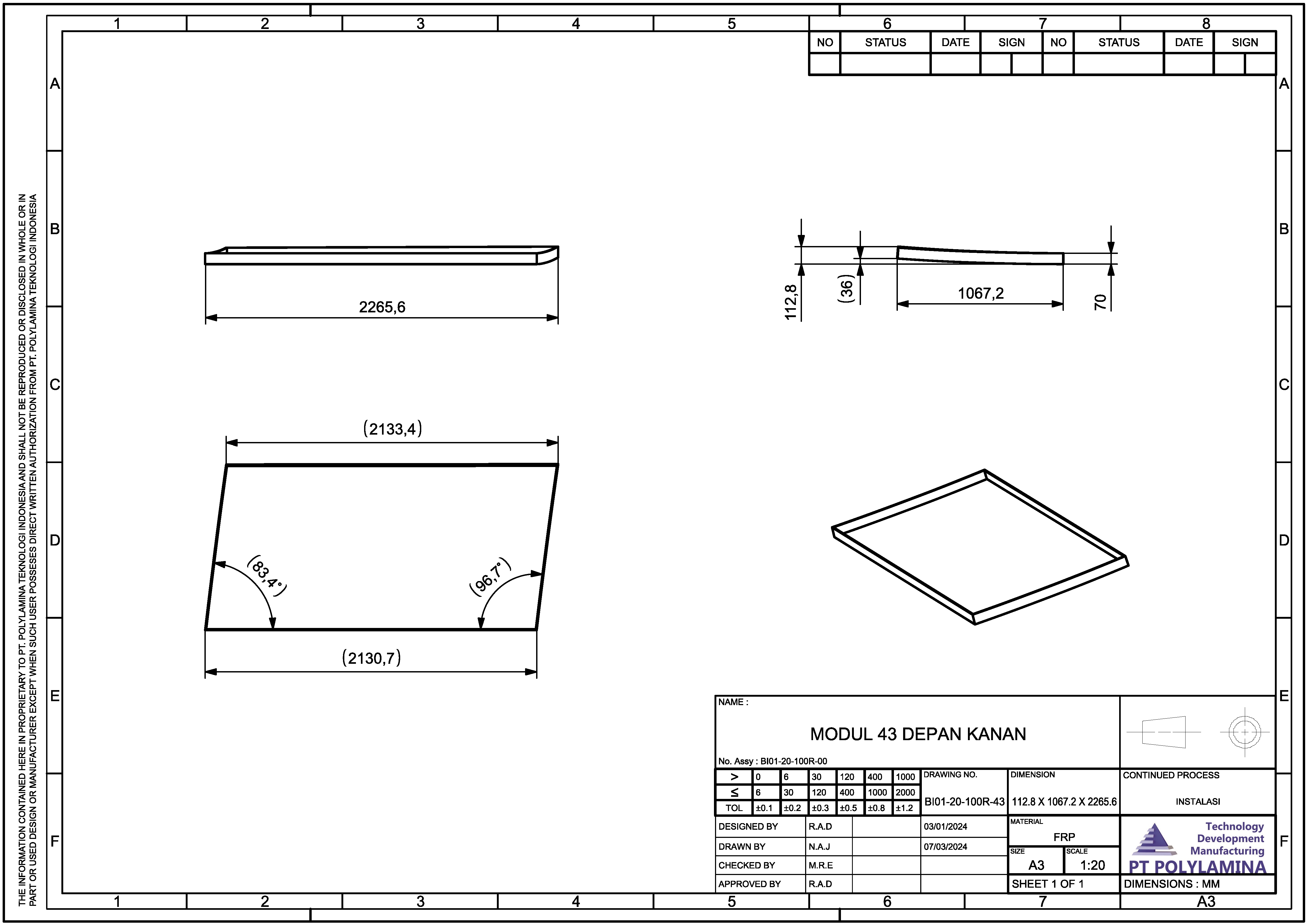

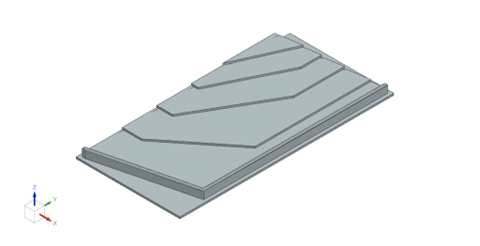

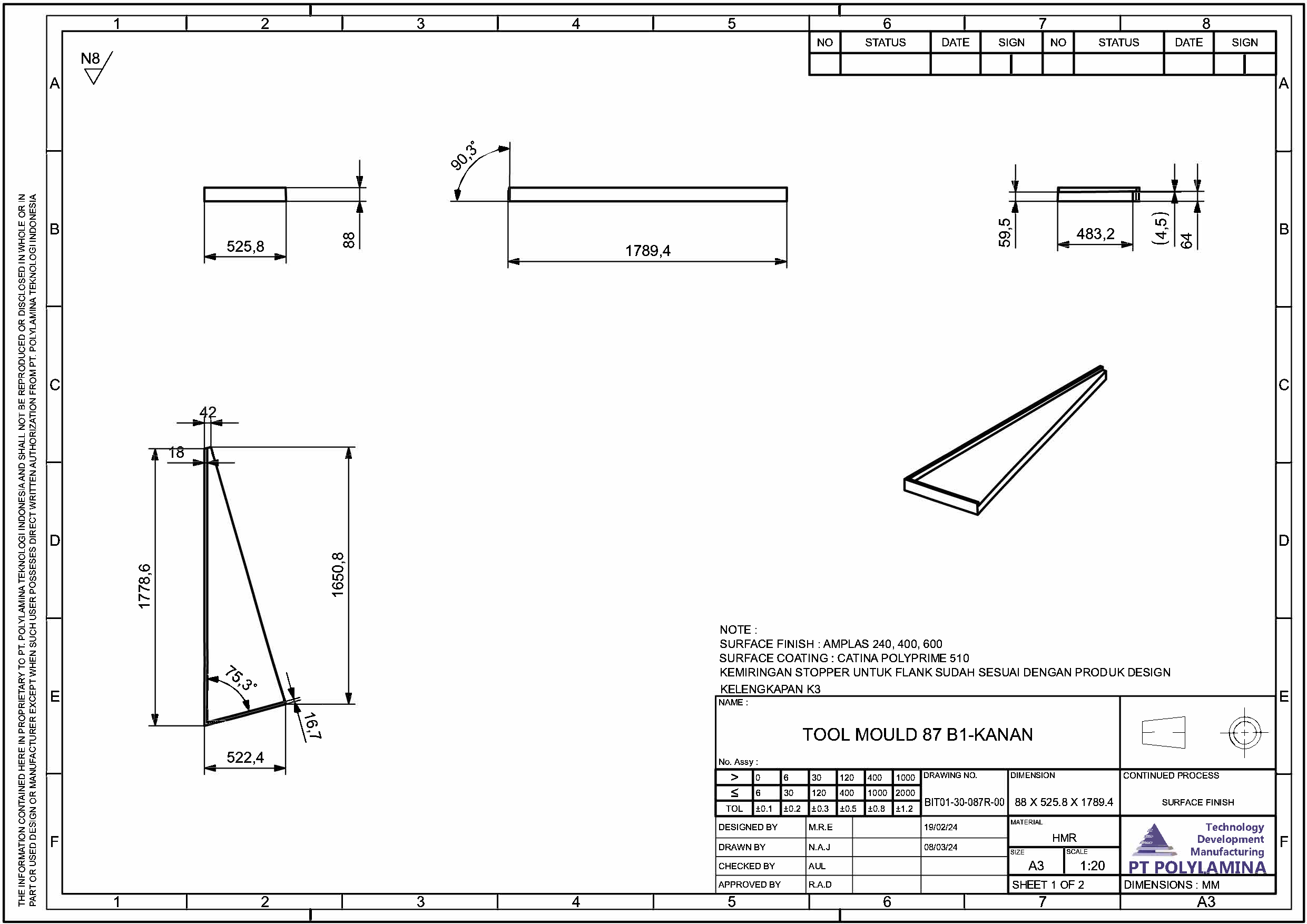

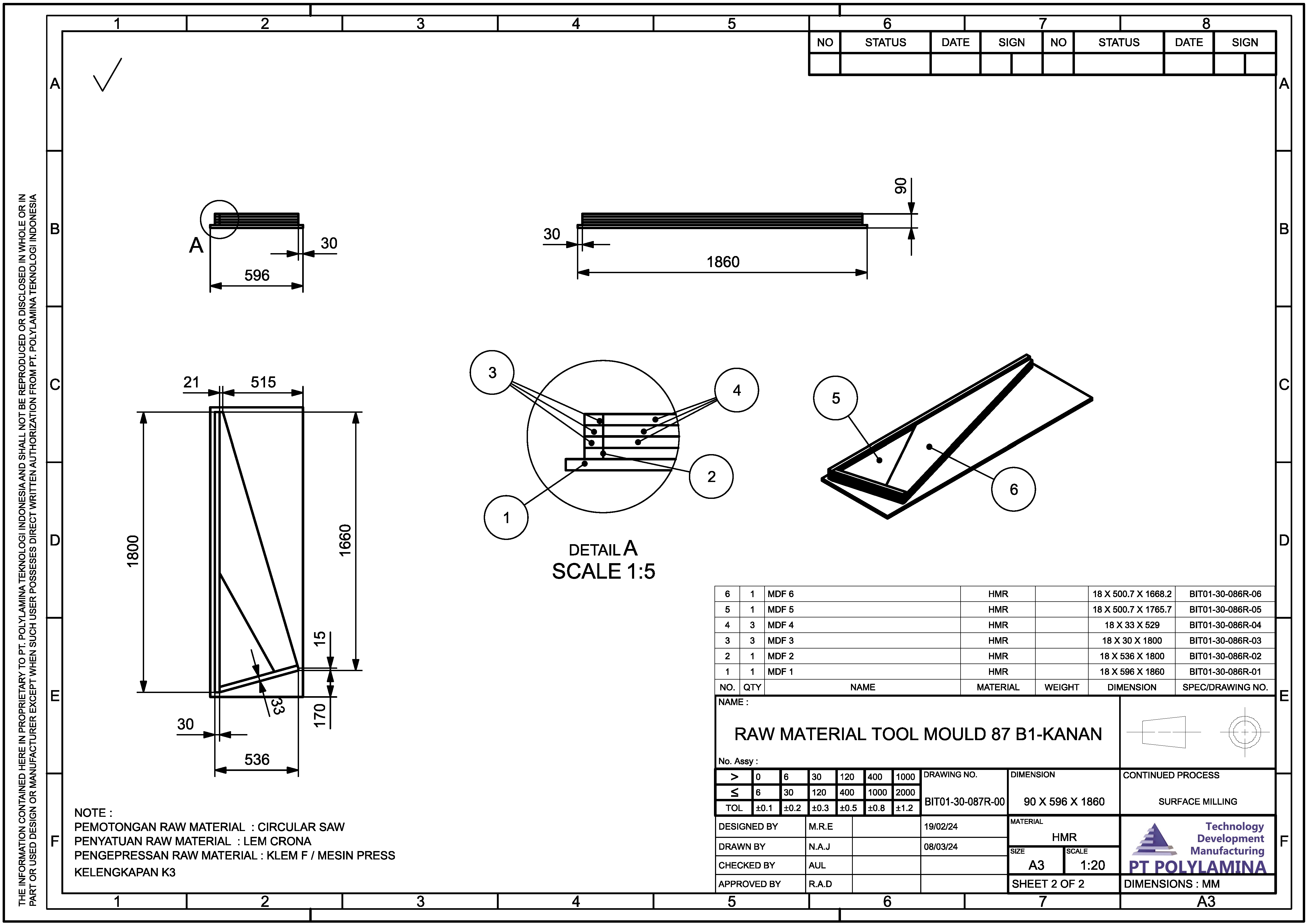

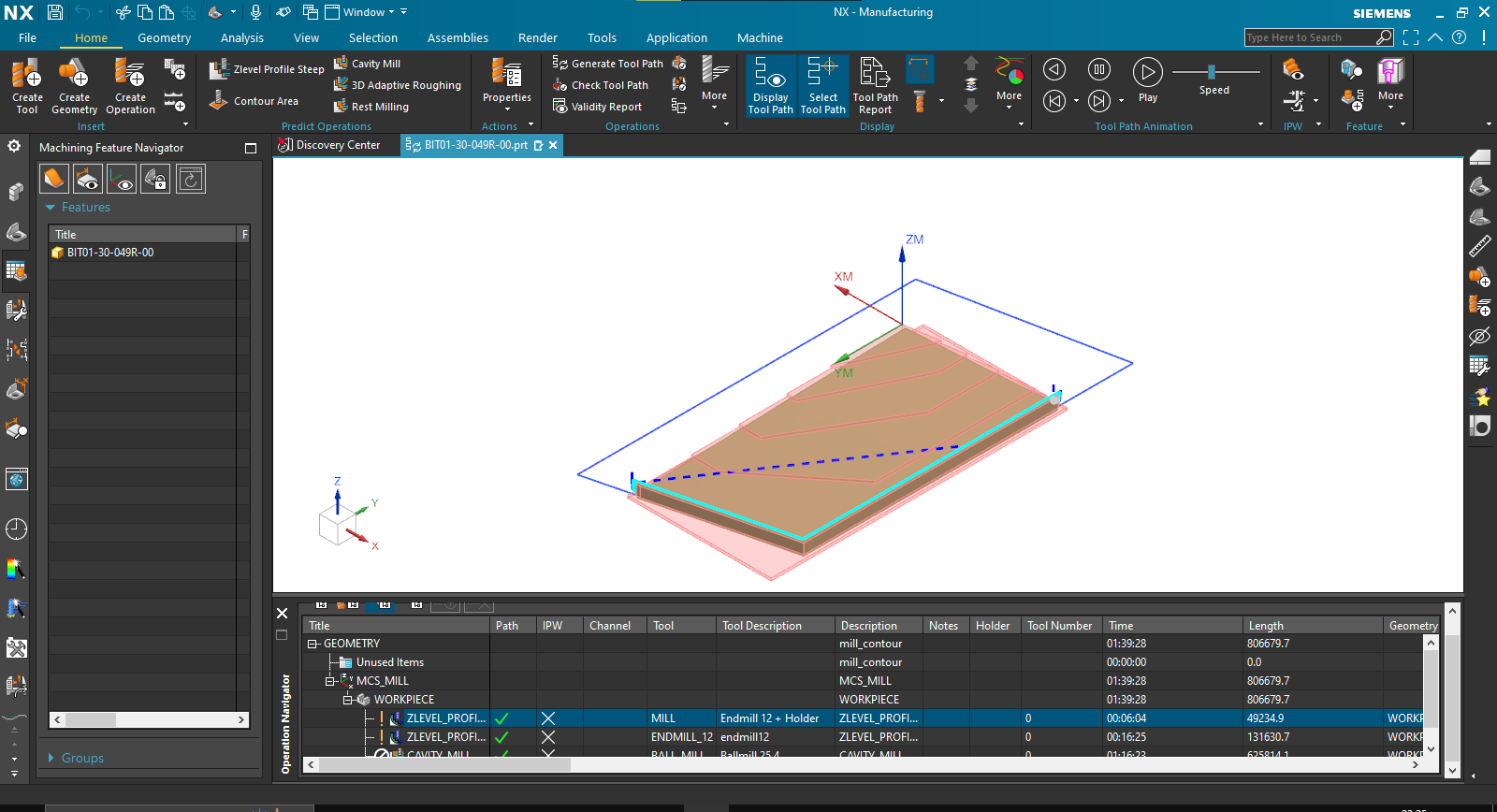

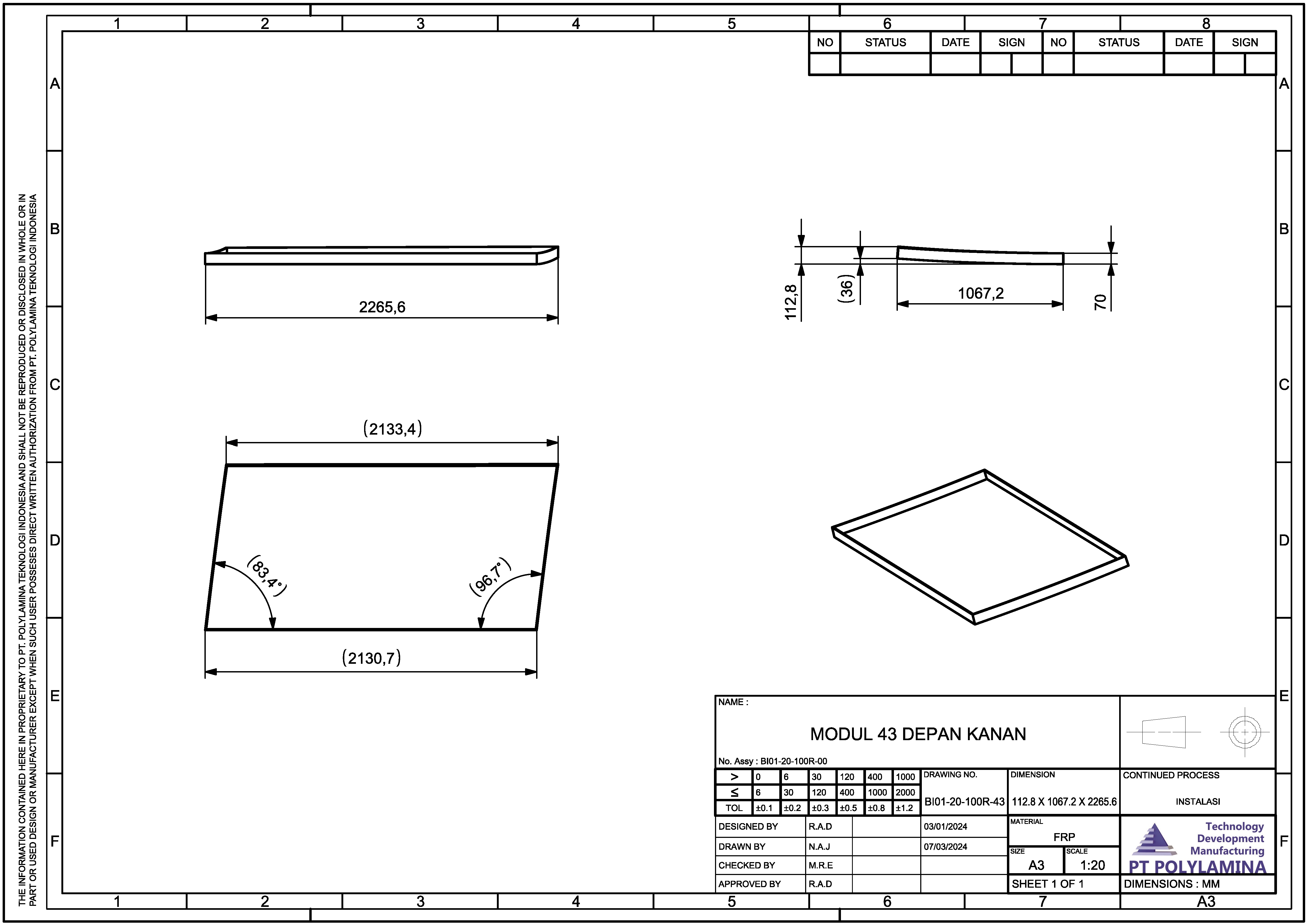

With a background in automation engineering from SMK Negeri 1 Cimahi, I have competed in and won technical competitions, proving my skills in PLC programming and electrical installations. My experience includes working as a Mechanical Intern at PT Lumbung Jaya International and as a Drafter at PT Polylamina Teknologi Indonesia, where I contributed to precision manufacturing, CAM processes, and control system simulations.

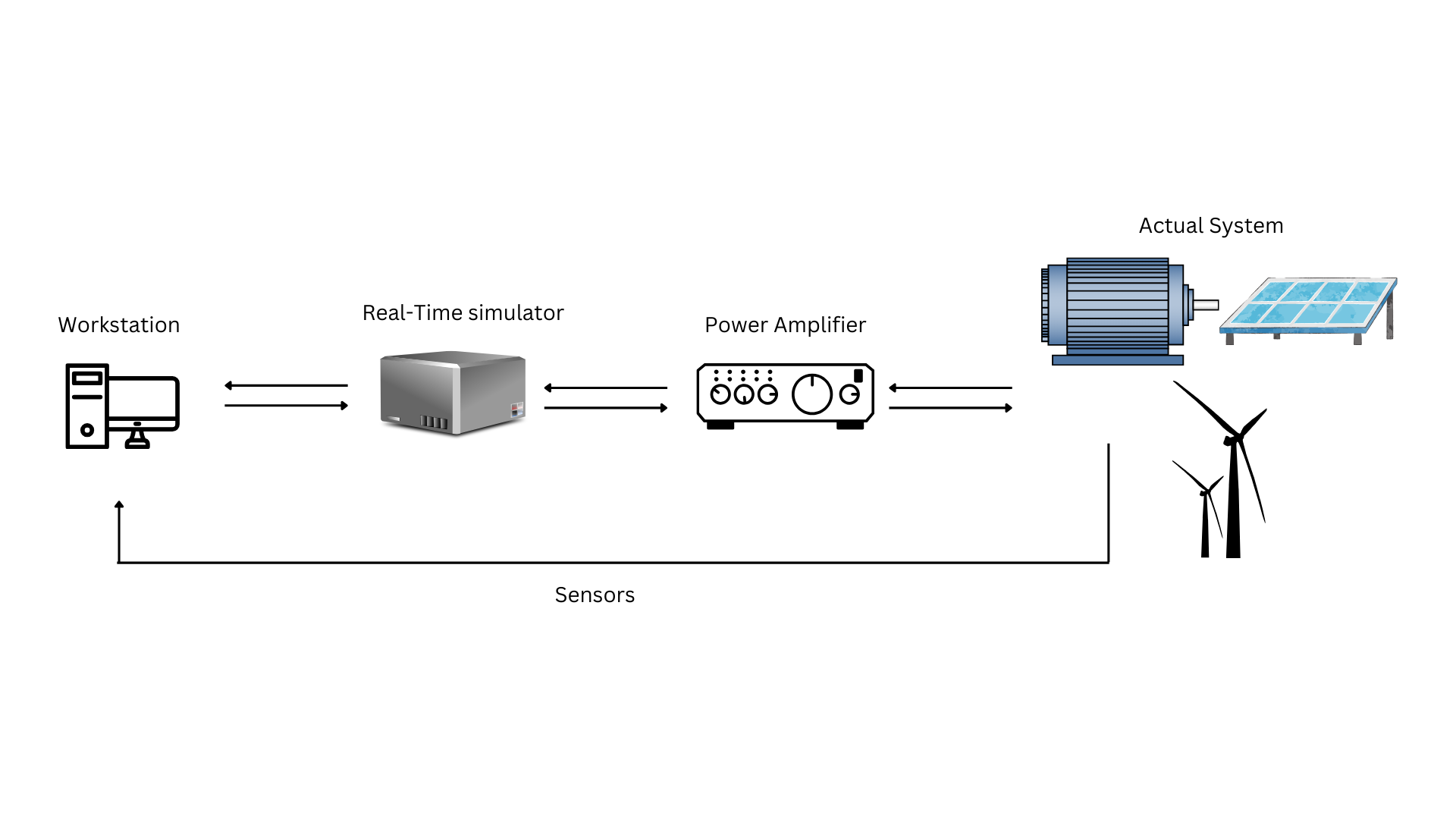

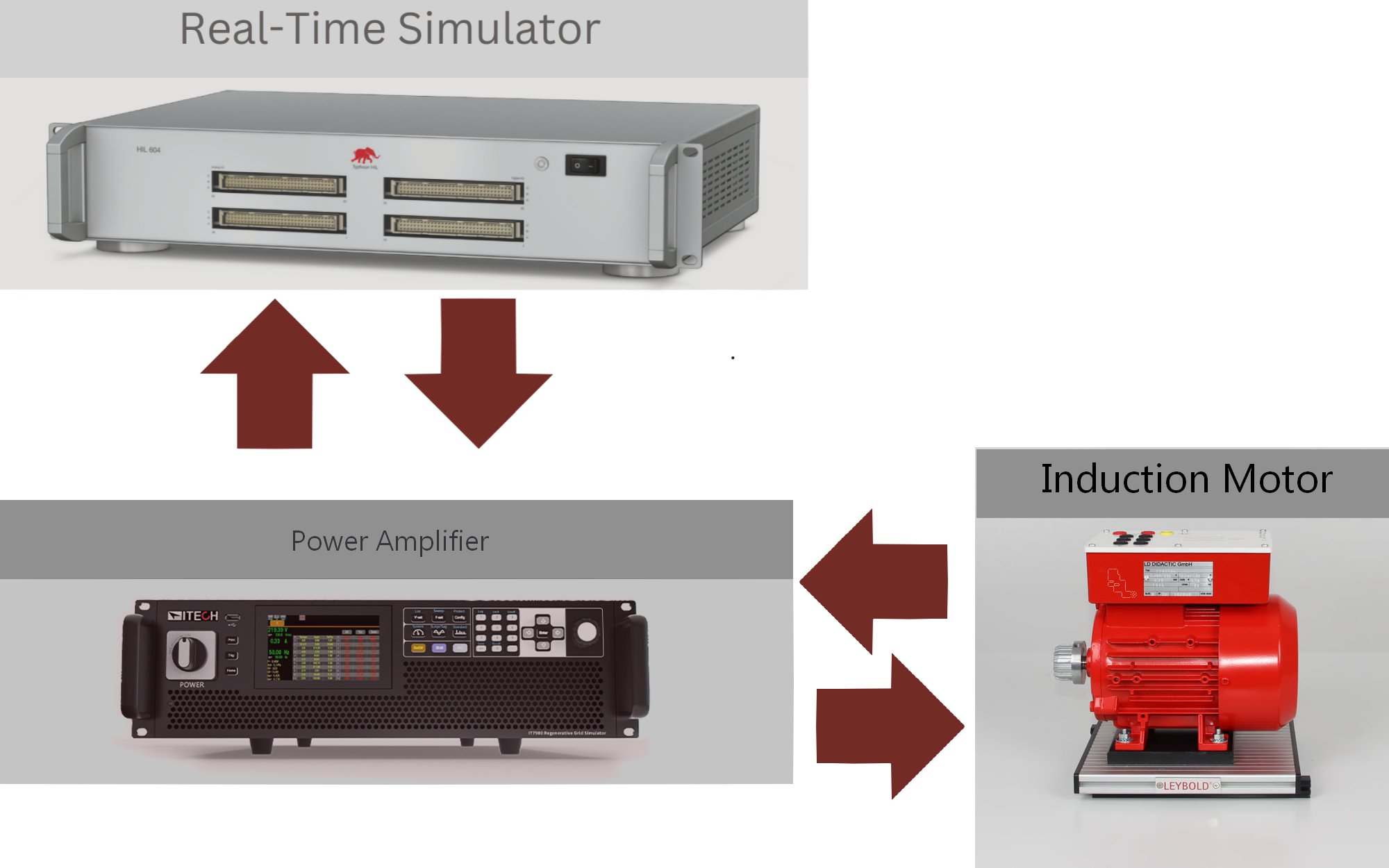

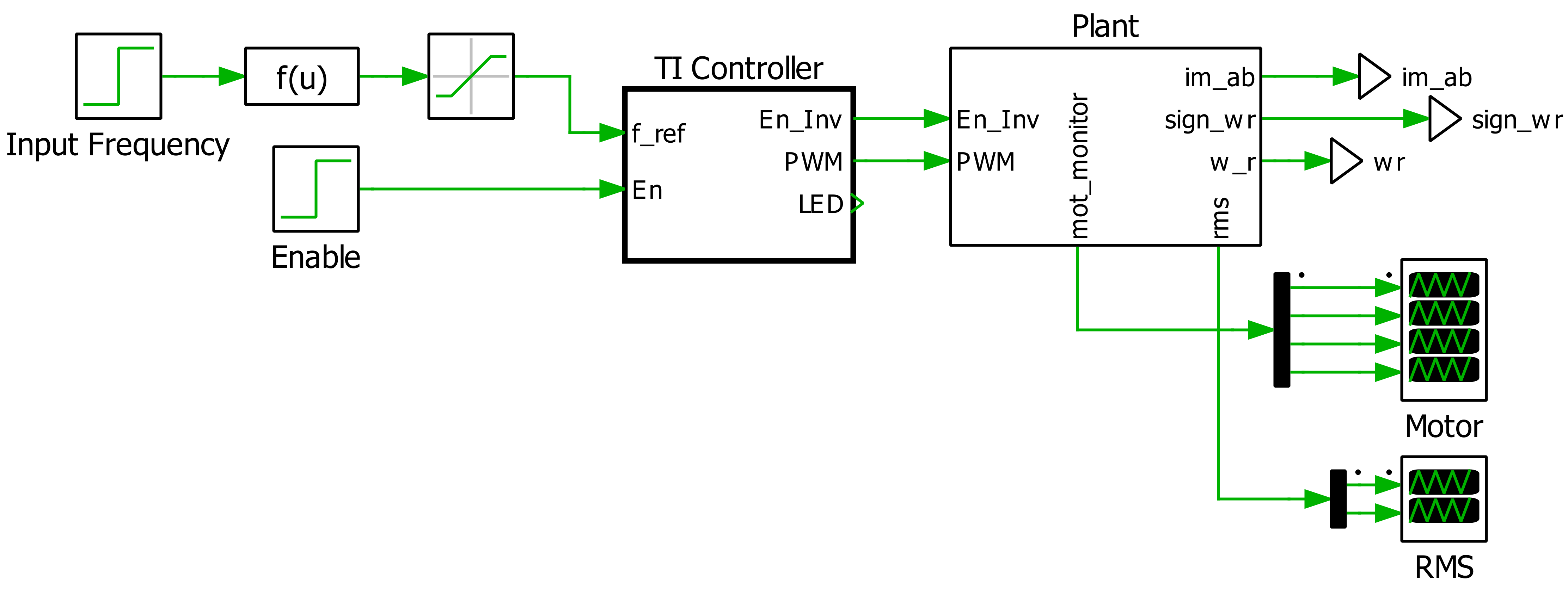

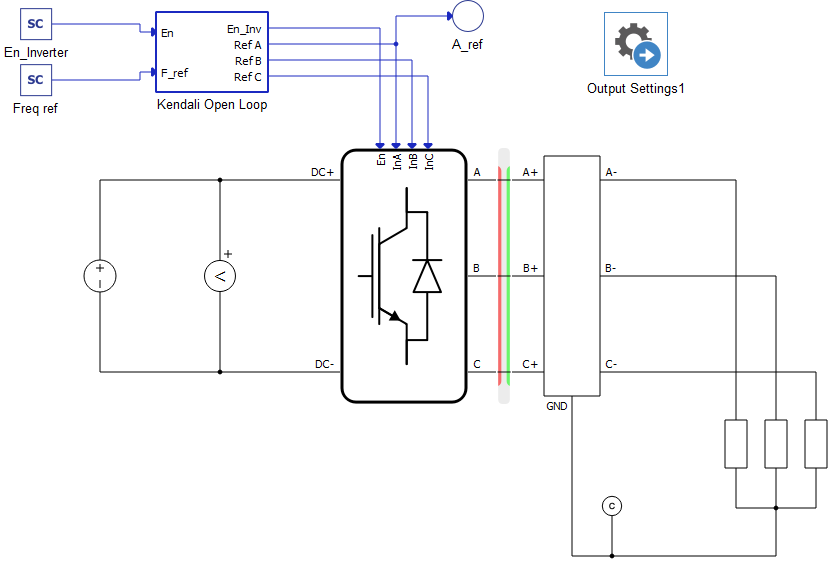

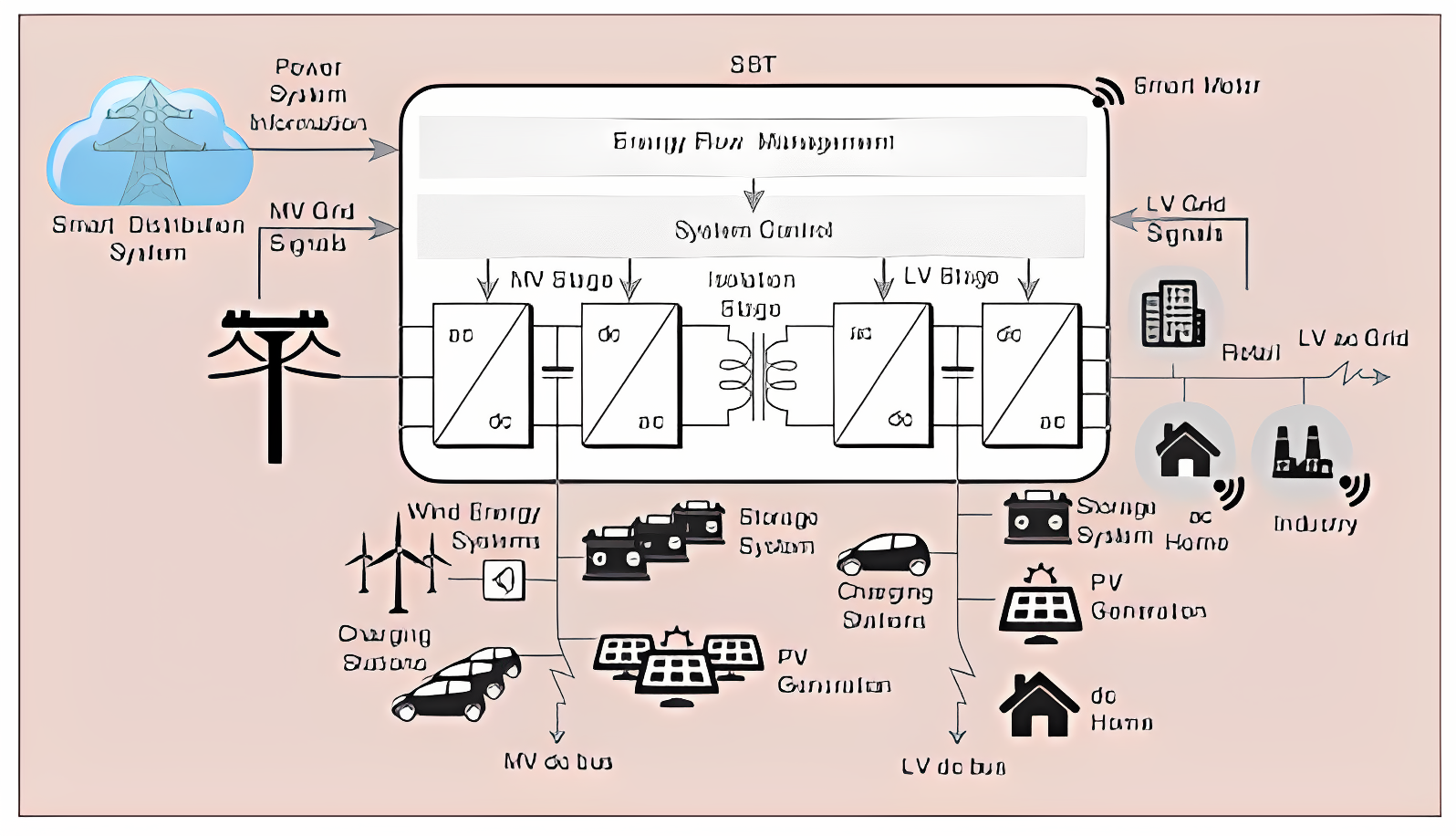

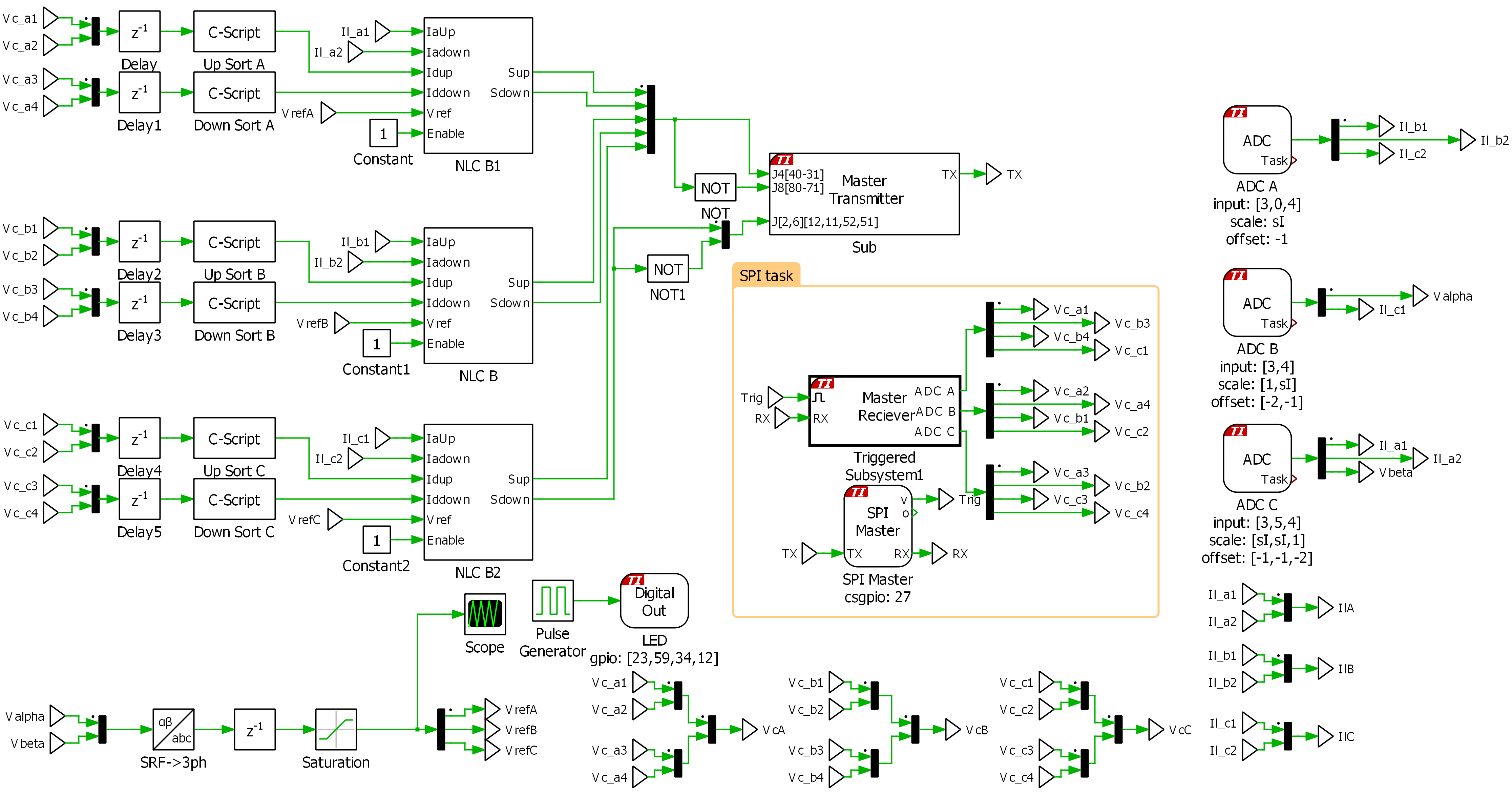

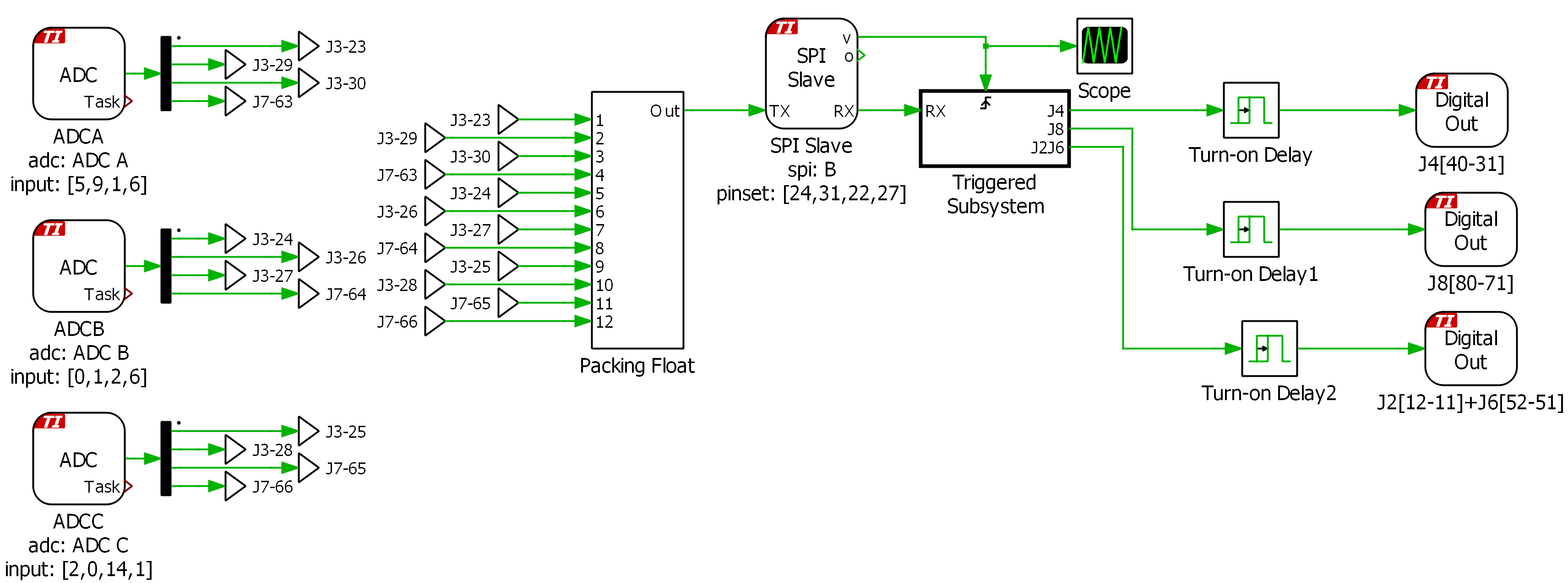

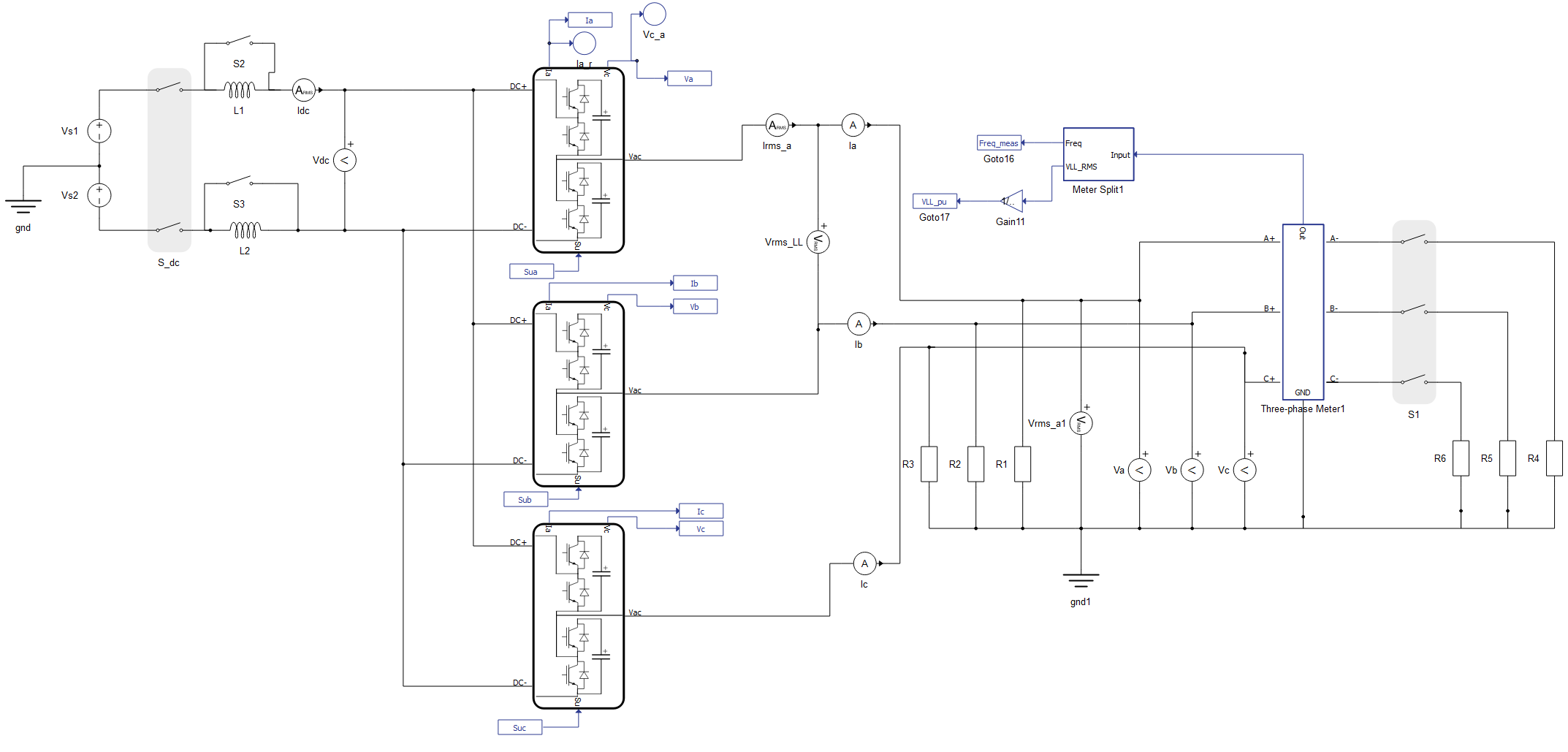

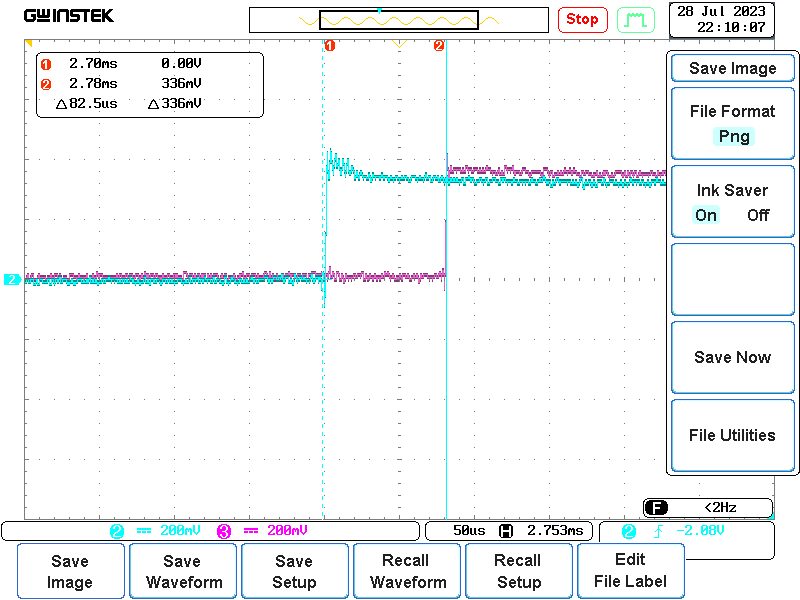

I am proficient in Python, C, MATLAB, and simulation tools like PLECS and Typhoon HIL, allowing me to tackle engineering challenges with efficiency. I also hold certifications in PLECS training, digital marketing, and network construction.